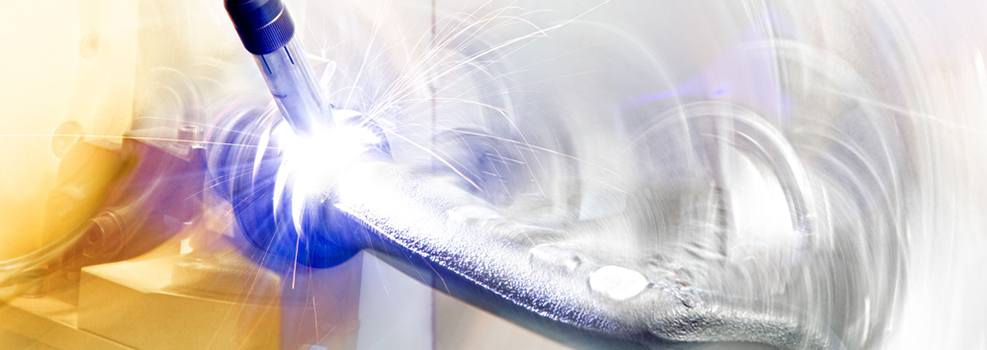

Braze Welding and Cladding

Braze welding is a welding process carried out for fusions only using filler metal, whilst the base metal is heated to a temperature below its melting point, adapting to allow a union with the filler metal.

The filler metal must always have a melting temperature which is lower than that of the base metal so the joint appears uniform: if the base metal is brought to the proper temperature (called wetting temperature), braze welding ensures the implementation of a specific bond between the two metals, capable of creating in the welded joint mechanical properties of the same kind and often even better than those of the base metal.

Filler metals generally used on steel, on cast iron and on copper and its alloys are alloys in copper, zinc and silicon or copper, zinc, nickel and silicon.

Main features of Braze Welding

Braze Welding is a welding process to be used when:

two different types of metal must be welded

unconfirmed metals must be welded

there is the need to reduce or limit deformations on the metals to be joined

minimum finishing is required on the joined part

there is the need to transfer low-melting material without varying the geometry of the gap on the metal base (for example, transferring non-magnetic material onto magnetic materials)

Cladding

Overlay welding also known as cladding, is a process where hard material is overlaid (overlay welding) on worn parts, or on parts intended for heavy strenuous use. The overlaying can be performed with MIG / MAG and TIG welding with filler material.

Tecno-Saldature is equipped for overlay welding, steel sheet cladding, overlay welds, recoating sheets, from small dimensional parts right up to performing overlay welding on any parts with a specific hardness and size required by the client.